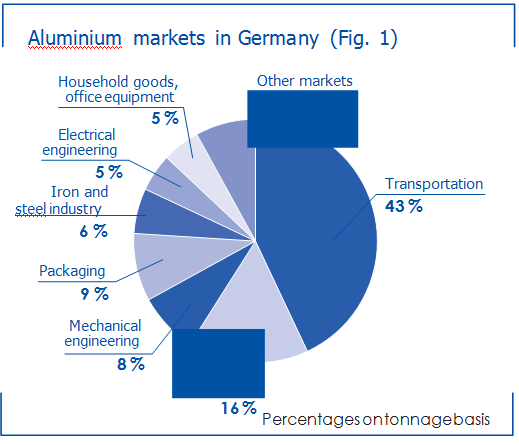

Of some 73,000 people employed in the German aluminium industry, about 15,000 work in the packaging sector. In 2004 the sector had a turnover of 1.8bn euros, representing around 14 per cent of the total turnover of the industry. This is equivalent to some 363,000 tonnes. About nine per cent of the total production of the aluminium industry is used in the packaging sector, which is thus the third largest market for aluminium products in Germany (Fig. 1).

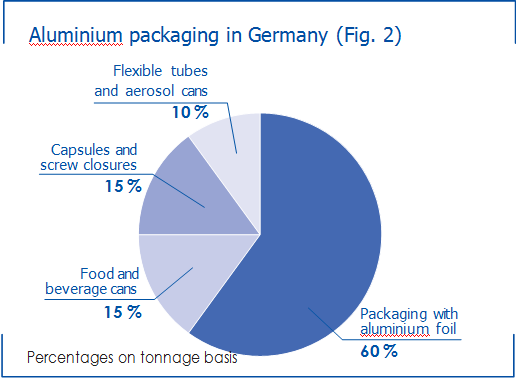

Some 60 per cent of the aluminium used for packaging is processed to foil or thin strip. The capsules and screw closures and the food and beverage cans segments each account for 15 per cent. Ten per cent goes into flexible tubes and aerosol cans (Fig. 2).

The process steps prior to the production of aluminium packaging, namely the process chain comprising (primary aluminium) metal production, casting and rolling, are de- scribed in Technical Information W 1 – The Metal Alumini- um. Therefore only the production of secondary aluminium will be dealt with here together with a brief description of the production of rolling ingots (continuous casting) and the rolling process. The manufacture of different types of aluminium packaging is then explained.

The production of recycled aluminium

Aluminium has a high intrinsic material value. This has meant that recycling aluminium has always been worth- while economically, especially since it can be remelted time and again without any loss in quality. The recycled material mainly comes from the transportation and build- ing and construction sectors. Nowadays, recycling rates of 85 to 95 per cent are standard in these fields of appli- cation. In recent years, thanks mainly to the recycling efforts of the Duales System Deutschland, one has been able to recover ever-greater amounts of aluminium from used packaging, so that the recycling rate in this sector is now over 70 per cent.

Pyrolytic recycling has proven to be successful in the case of aluminium scrap that is dirty or covered with a layer of paint or lacquer, particularly if it is laminated with other packaging materials (Fig. 3).

Aluminum in the packaging industry – Manufacture, Use, Recycling

Foreign matter detrimental to aluminium is first separated mechanically from the shredded material, which is then subjected to rotary kiln pyrolysis with subsequent bright annealing. The scrap is then carbonised at a temperature of 500 °C and converted into aluminium, pyrolysis coke and pyrolysis gas. The gas is burnt in a downstream com- bustion chamber at a temperature of at least 1,200 °C and thus provides heat for the process. As for the solid mate- rials, the pyrolysis coke and aluminium are separated mechanically and thermally and the uncoated aluminium is melted in the melting facility.

The unit comprises a two-chamber system that can be operated with only small quantities of flux. The molten aluminium is subsequently analysed and refined; the salt slag produced during melting is processed and recovered. Refining of the molten aluminium is carried out using an argon gas treatment in order to remove any remaining impurities. The argon is fed into the melt and this flushes out gases and oxides. Finally, the metal is transported to the foundry.

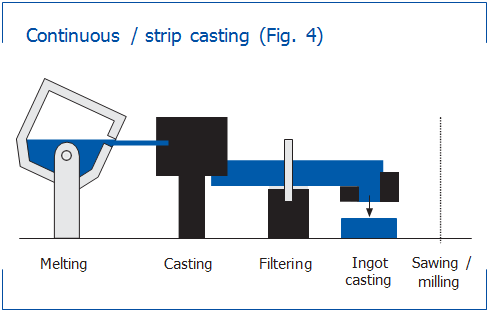

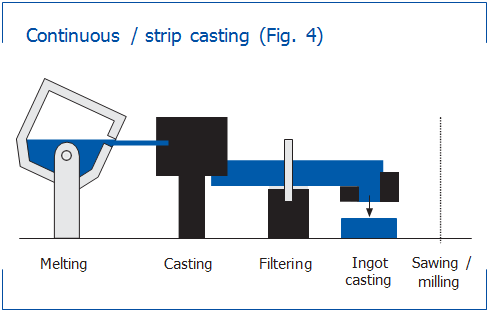

As a high-purity melt is important in rolling processes, primary aluminium or recycled metal from carefully graded scrap – for example used beverage cans – is usually used for rolled products. Lacquered, coated or oily raw mate- rials, such as process scrap that does not originate from the DSD fraction, is melted in so-called triple-chamber hearth melting furnaces comprising smelting, main and pump hearths. The scrap is melted without any air intake (in other words with an oxygen deficiency) in the smelting hearth, from which the low-temperature carbonisation gases are extracted and burnt in the main hearth of the furnace with the help of natural gas burners. One can forego the use of fluxes if the scrap is not heavily contam- inated. As there are no open flames in the smelting hearth, the metal recovery is very high. There is an argon treat- ment here, too, before the metal goes to the foundry.over its whole cross-section. Only the surface solidified by water cooling is irregular and thus has to be post-worked: both ends of the ingot are sawn off to remove irregulari- ties arising from the casting process and the cast skin (the so-called skull) is removed on all sides by milling. (Fig. 4)

The vertical continuous casting process described here is the preferred method of producing ingots worldwide. In addition, there are horizontal continuous casting plants in which the strands are allowed to grow in a horizontal direction. In the various types of strip casting process, molten aluminium is cast between two water-cooled steel strips, rotating steel moulds or rolls and, depending on the process used, strip 6 to 30 mm thick solidifies at a low flow rate; the strip is subsequently rolled directly. Casting wheels (so-called rotary Rigamonti casting wheels) are used to cast strips for slug production, for example for aerosol cans and tubes; the wheels have a recess, which is cov- ered by a steel strip, whose width and depth corresponds to the dimensions of the strip. Molten metal at 750 °C is guided to the inlet pouring gate of the casting wheel. The casting wheel and the steel strip are water-cooled. Thus, when the aluminium leaves the casting wheel its surface is already solidified and can be removed without any sup- port at a temperature of 500 °C. The cast strip is hot rolled further, cooled to about 50 °C in a water bath, cold rolled to make it smooth and achieve the desired thickness, and then coiled.

Various shapes of rolling ingot can be cast in computer controlled continuous casting plants, in which the casting process is performed completely automatically. The casting device comprises a water-cooled mould with a base that can be lowered. The molten aluminium is poured slowly into the mould and solidifies on the walls and base; it thus acts like a beaker whose contents are still molten. While molten metal is continuously poured into the mould at the top, the base is lowered uniformly at such a rate that the level of the molten metal in the mould remains constant. This leads to the formation of a strand or ingot, which is sprayed with water from all sides to cool it completely. Solidification proceeds from the bottom to the top into the innermost parts of the ingot. In this way, an ingot is pro- duced that is fine-grained, compact and free from pores over its whole cross-section. Only the surface solidified by water cooling is irregular and thus has to be post-worked: both ends of the ingot are sawn off to remove irregulari- ties arising from the casting process and the cast skin (the so-called skull) is removed on all sides by milling. (Fig. 4)

The vertical continuous casting process described here is the preferred method of producing ingots worldwide. In addition, there are horizontal continuous casting plants in which the strands are allowed to grow in a horizontal direction. In the various types of strip casting process, molten aluminium is cast between two water-cooled steel strips, rotating steel moulds or rolls and, depending on the process used, strip 6 to 30 mm thick solidifies at a low flow rate; the strip is subsequently rolled directly. Casting wheels (so-called rotary Rigamonti casting wheels) are used to cast strips for slug production, for example for aerosol cans and tubes; the wheels have a recess, which is cov- ered by a steel strip, whose width and depth corresponds to the dimensions of the strip. Molten metal at 750 °C is guided to the inlet pouring gate of the casting wheel. The casting wheel and the steel strip are water-cooled. Thus, when the aluminium leaves the casting wheel its surface is already solidified and can be removed without any sup- port at a temperature of 500 °C. The cast strip is hot rolled further, cooled to about 50 °C in a water bath, cold rolled to make it smooth and achieve the desired thickness, and then coiled.

The rolling process includes hot and cold rolling; the prod- ucts are plate (thickness >6 mm), strip (0.021 to 6 mm) and foil (<0.021 mm). The term “thin strip” is used for thicknesses from 0.2 mm down to 0.021 mm.

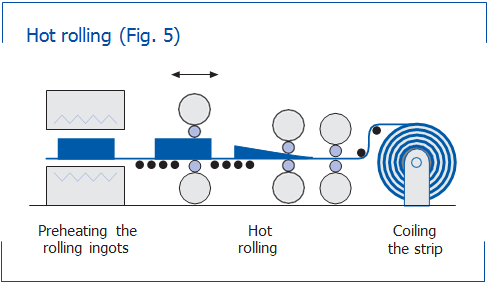

The starting material for hot rolling are continuously cast ingots, which can be up to 9 m long, 2.2 m wide and 600 mm thick, and weigh up to 30 t. Depending on the demands made by subsequent processing, the ingots are either commercially pure aluminium (max. 1% impurities) or alu- minium alloys. The ingots are heated to a temperature of 500 to 600 °C and then rolled until they are over 100 m long and several centimetres thick in a reversible blooming mill stand (four-high hot-rolling stand) in a dozen or two passes. In doing so, reductions per pass of over 50 per cent are possible. Cropping shears cut off the ends of the strip that opened up; this process scrap is then melted down again. The billets are subsequently rolled on multiple- stand finishing trains to produce hot strip that is typically between 2.5 and 8 mm thick; this strip is subsequently wound to produce a coil with a maximum diameter of 2.7 m weighing 24 t. (Fig. 5)

Once the coil has been cooled to room temperature, it is subjected to cold rolling on a four-high stand. Steel back- up rolls ensure that the high pressure does not cause the smaller diameter working rolls to bow out. During rolling, the deformation energy causes the metal to heat up to over 100 °C, which is why coolants are used. After several pas- ses one finally obtains thin strip (DIN EN 485-1), can stock (DIN EN 541) or foilstock (EN 12482), which is trimmed and coiled. If the strip is not intended for further processing internally, it is coated or lacquered if necessary prior to being shipped to the client.

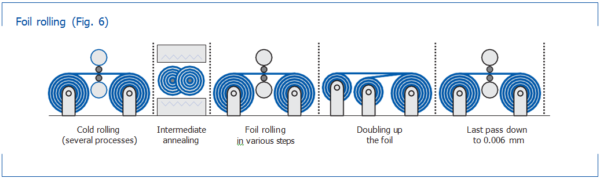

Forming causes hardening, which results in the strip becoming hard and brittle. In foil rolling mills the thin strip is subjected to intermediate annealing, which causes recrystallisation, in order to make it soft and ductile again. Aluminium foil (DIN EN 546) is produced in a series of rolling stages on single or tandem roll stands at speeds of up to 2,500 m/min: the most technically demanding foil is less than 0.006 mm thick and thus only about a tenth of the thickness of a human hair. Rolling oils provide cooling and lubrication and are circulated in a closed loop. The final pass is carried out using a “sandwich process”.

As the material is very thin, two coils are fed simultane- ously through the foil rolls (Fig. 6). This produces the dif- ferent finishes that one is familiar with from household foil: the sides that come into contact with each other are matt, whereas the sides that come into contact with the rolls are shiny.

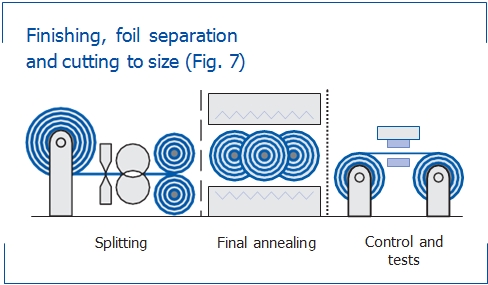

Following the final pass, the individual foils are separated again during slitting and then cut to the width and length required by the client. After passing through the finishing rolls, the foil is usually annealed to facilitate further proces- sing; this treatment also leads to vaporisation of residual rolling oil and renders the foil completely sterile. (Fig. 7)

Depending on the specific requirements, the foil and strip can be mechanically or chemically treated, lacquered, laminated, coated, processed with other materials to pro- duce foil laminates, embossed or printed. In addition to decorative purposes, these measures serve to improve the mechanical loading capability and chemical resistance or to produce specific properties such as heat sealability. Some aspects of surface treatment and conversion are outlined briefly below.

4.1 Degreasing

The degreasing of oily or greasy surfaces is carried out using aqueous cleaners. The aim is primarily to remove organic compounds such as rolling oil residues.

4.2 Pickling

The aim of pickling is to remove oxide layers. As the protec- tive oxide layer is only stable over the pH range 5 to 8, the surface treatment can be carried out using either alkaline or acidic solutions. After pickling, the surface is rinsed with water and neutralised with nitric acid solution.

4.3 Lacquering and colouring

In the case of protective lacquering, colourless, thin layers of lacquer are applied to the aluminium foil. These layers are not completely free from pores and offer only limited resistance to chemical attack but provide a good adhesive base for printing. If greater chemical resistance is required, thicker film thicknesses are applied. Thermoplastic (plas- tic) lacquers ensure good heat sealability. When it comes to colouring, additional pigments are incorporated in the lacquer binder. Opaque colouring is carried out using pig- mented lacquers; in the case of transparent colouring, the metallic character of the surface is maintained.

It is always necessary to carry out a thorough surface treat- ment including degreasing and pickling prior to lacquer- ing. In order to apply lacquer systems to aluminium foil, they are mixed with organic solvents; these are released again later during drying and returned to the production loop via extraction and recovery systems. Low-solvent and solvent-free lacquers are increasingly being used.

4.4 Lamination

In the case of lamination, aluminium foil and strip are bonded with other materials such as plastic films and paper. The various forms of lamination include adhesive, lacquer, wax and hot-melt lamination.

4.5 Coating

In the case of coating, a plastic is applied to the alumini- um foil either in molten form, as a dispersion or as a solu- tion. Depending on the specific demands made on the packaging material, several layers of different plastics are used.

4.6 Printing

The two most important printing processes used in foil conversion are flexo and gravure printing. Flexo printing allows three-dimensional shapes to be printed and is also economical for small production runs. Gravure printing is particularly well suited for large production runs and is striking because of the high quality of its colour reproduc- tion.

4.7 Embossing

The embossing of foil and thin strip is carried out using engraved or etched steel embossing rolls and a counter roll made of resin-bonded paper. It causes items such as company logos, trademarks and slogans to stand out three dimensionally over the surface. The process is being increasingly used to “upgrade” packaging in order to set the contents of a pack apart from those of the competi- tion.

Further outstanding characteristics of aluminium as a packaging material are:

■ its light weight, which reduces transport costs

■ its high thermal conductivity, which reduces the energy requirement for hot sealing and sterilisation as well as for freezing, cooling and heating in the pack

■ its high reflectivity of light and UV rays

■ its corrosion resistance due to the natural oxide layer that forms spontaneously on aluminium; the level of protection can be increased further by foil conversion

■ its chemical resistance to the pack contents

■ its neutral taste

■ its good formability whilst at the same time maintaining shape stability, which proves useful for example when deep drawing containers or wrapping hollow shapes

■ the resistance of containers to breakage and pressure

■ the good printing and embossing properties of foil and strip

■ its excellent recyclability.

DIN EN 546-2 covers the alloys used for foil and their mechanical properties.

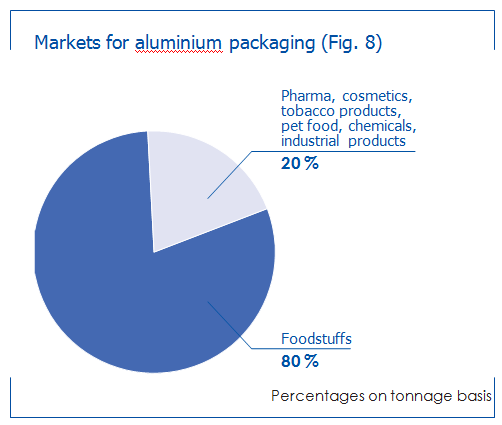

Aluminium is used as a packaging material for completely different types of goods: foodstuffs, drinks, pharmaceuti- cals, cosmetics, pet food and tobacco products as well as chemicals and industrial products (Fig. 8). With foodstuffs, where foil in particular is used, it is the complete barrier performance that also protects perishable goods such as dairy products. Exactly the same applies for medication that requires reliable protection against light, moisture

and gases even under extreme conditions such as those experienced in the tropics.

In the case of chemical products such as laboratory chem- icals, agrochemicals, sealants and adhesives, aluminium bottles, cans and cartridges are used. Here, the materi- al’s resistance to breaking, diffusion and pressure play a decisive role.

Aerosol cans and tubes made from aluminium are the pre- ferred packaging for pharmaceuticals, hygiene and/or bodycare products and cosmetics.

Aluminium foil is used either as a single material or as a composite material in combination with other packaging materials such as paper and/or plastics. Such “tailored” composites combine the positive properties of differing materials, usually with the use of less material. In this way they offer maximum packaging benefits with minimum use of material.

Rolled products in general for packaging are covered by the EN 14287 standard and foil by DIN EN 546. The EN 601 and EN 602 standards lay down limiting values for the indi- vidual alloying elements that have to be observed if an alloy is to be allowed to come into contact with foodstuffs.

Rigid aluminium packaging includes beverage, food and aerosol cans as well as closures. They are produced by deep drawing and impact extrusion.

7.1 Beverage cans

Beverage cans are used above all for beer and carbonated soft drinks. In the past this form of packaging has increas- ingly taken over other product segments such as iced teas and coffee-containing refreshments. In Europe, sales in- creased six-fold between 1975 and 1997, with annual growth rates of ten per cent or more; 37.5bn cans –tinplate and aluminium – were sold in western and eastern Europe in 2003. The aluminium beverage can’s market share in Europe is 62 per cent, although it is only about 13 per cent in Germany.

The aluminium beverage can has undergone numerous innovative developments: with the tear-open lid, which is made of aluminium for both types of can material, one thinks of the development from the ring-pull can to the stay-on-tab system or the LOE lid with its enlarged drink- ing aperture. Savings on materials due to thinner walls of the aluminium can body and a necked-in top have led to lower production costs and reduced transport weight. Em- bossed aluminium beverage cans are appearing on super- market shelves in increasing numbers. Innovative coating processes produce surfaces that have a wet-look appear- ance or, for example, feel like an orange. There are alu- minium beverage cans with thermo-sensitive lacquers that indicate whether the temperature is appropriate for drinking and cans with luminescent paints that light up in the dark when illuminated with UV light. The pack itself becomes an effective marketing instrument that can pos- itively influence a brand’s image.

7.1.1 Manufacture:

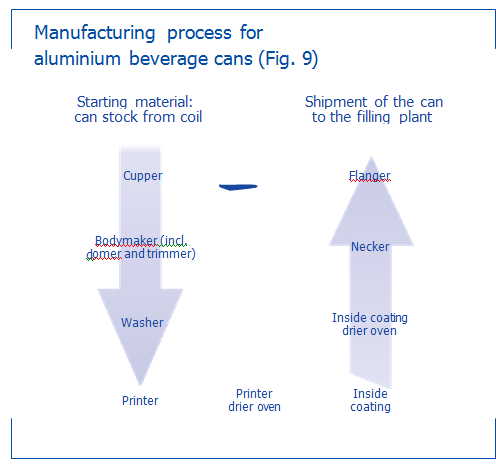

Aluminium beverage cans are produced by deep drawing as a two-part can with a crimped on tear-off lid (Fig. 9). The starting material is mill-finished strip containing manganese and magnesium as alloying elements for high strength and ductility. Because of the large degree of material defor- mation that takes place during the forming process, de- greasing, lacquering of the interior and exterior of the can, as well as the printing of the can body are first carried out on the finished can body.

First of all, so-called cups are cut from the pre-greased aluminium strip and shipped to the can manufacturer. Can manufacture is carried out by a deep drawing process in which the cups are drawn through dies using a punch to produce a hollow body in the shape of the punch. The process takes place in several steps, with the cups being drawn to can bodies with ever-smaller diameters, ever- thinner walls and ever-greater lengths. The can body is then trimmed to the exact height required. About 2,000 units a minute can be manufactured in this way on modern production lines.

Subsequent washing and drying remove the lubricant. The can is then subjected to external base coating, drying in hot air ovens, printing with up to six colours, another lacquering treatment and final drying. The interior of the can body is also subjected to a protective lacquer to avoid any direct contact between the drink and the metal. The can rim is then necked in and flanged outwards in order to enable the lid to be attached after filling. Finally, a detailed quality control is carried out to examine the can body for pores or cracks.

The next step is to ship the cans to the client, who fills and seals the cans. In contrast to the can body, the can lids are produced from pre-lacquered aluminium strip. In coil coat- ing plants, the strip is coated on both sides with client- specific lacquers at speeds of 200 m/min. The basic lid shapes with a smooth surface (shells) are stamped out of strip or sheet. The basic shape is produced in a so-called shell press: the edges are curled so that they can be seamed onto the can rim later. A sealant is then sprayed onto the inside rim of the shell. The inside of the shell is scored where the drinking aperture is to be so that the tab can be pushed through easily and without any risk of injury. The tab itself is produced separately in numerous work- ing stages using an automatic machine. It is attached to the lid by feeding a strip of tabs together with the shells into a second automatic machine, where the tab is attached to the end. Finally, the finished lids are sealed onto the filled cans.

7.2 Food cans

Like beverage cans, food cans made from aluminium alloys (AlMnMg) are made in two pieces. For decades they have been produced mainly as relatively flat containers for tinned fish and pasty foodstuffs; nowadays, however, the range of products has multiplied both in terms of the food- stuffs packaged and the size and shape of the cans.

The cans are deep drawn from sheet 0.2 to 0.3 mm thick. In principle, the process is the same as that for producing beverage cans. The sheet is pre-treated before being deep drawn and is subsequently lacquered and/or plastic coated and printed. As far as the closures are concerned, the cans have full-aperture tear-off lids with differing types of tear- open tabs: e.g. with a grooved surface for better grip or with a finger ring. Two-component systems comprising a membrane made of thin aluminium strip and an aluminium ring are an alternative to conventional can lids. The mem- brane strip is either colourless on the outside or coloured

Like beverage cans, food cans made from aluminium alloys (AlMnMg) are made in two pieces. For decades they have been produced mainly as relatively flat containers for tinned fish and pasty foodstuffs; nowadays, however, the range of products has multiplied both in terms of the food- stuffs packaged and the size and shape of the cans.

The cans are deep drawn from sheet 0.2 to 0.3 mm thick. In principle, the process is the same as that for producing beverage cans. The sheet is pre-treated before being deep drawn and is subsequently lacquered and/or plastic coated and printed. As far as the closures are concerned, the cans have full-aperture tear-off lids with differing types of tear- open tabs: e.g. with a grooved surface for better grip or with a finger ring. Two-component systems comprising a membrane made of thin aluminium strip and an aluminium ring are an alternative to conventional can lids. The mem- brane strip is either colourless on the outside or coloured

Like beverage cans, food cans made from aluminium alloys (AlMnMg) are made in two pieces. For decades they have been produced mainly as relatively flat containers for tinned fish and pasty foodstuffs; nowadays, however, the range of products has multiplied both in terms of the food- stuffs packaged and the size and shape of the cans.

The cans are deep drawn from sheet 0.2 to 0.3 mm thick. In principle, the process is the same as that for producing beverage cans. The sheet is pre-treated before being deep drawn and is subsequently lacquered and/or plastic coated and printed. As far as the closures are concerned, the cans have full-aperture tear-off lids with differing types of tear- open tabs: e.g. with a grooved surface for better grip or with a finger ring. Two-component systems comprising a membrane made of thin aluminium strip and an aluminium ring are an alternative to conventional can lids. The mem- brane strip is either colourless on the outside or coloured

with a protective lacquer, and sometimes printed as well; on the inside there is a plastic peel coating. The lids can thus be removed as easily as can the lids from yoghurt pots. The food cans are retortable, i.e. they are suitable for sterilising the foodstuffs in autoclaves.

7.3 Aerosol cans

In 2004 about 1.93bn aluminium aerosol cans were pro- duced in Europe. This is equivalent to a market share of 43 per cent. The cosmetics industry is the largest user with some 80 per cent; in addition, aerosol cans are used as packaging for chemical and pharmaceutical products as well as foodstuffs (Fig. 10).

Aerosol cans are produced as a monobloc without any seam or joints by means of impact extrusion. This enables them to withstand the highest possible internal pressures of up to 18 bar. They are mainly manufactured from com- mercially pure aluminium (99.5% purity) and sometimes they are made from aluminium alloys. As is the case with the manufacture of flexible tubes, the diameter of the slug processed depends on the desired can size. In addition to their size, aerosol cans differ above all in the shape of their shoulders (round, spherical, sloping, stepped and ogival) with neck apertures for 1-inch or 20-mm valves. The cans can now be manufactured in completely new shapes and complex designs thanks to new butting and embossing technologies.

7.3.1 The process steps in detail:

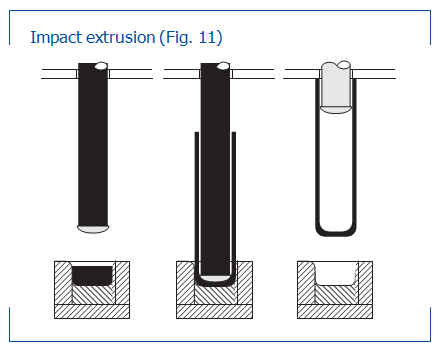

A circular disc – called a slug – stamped out of aluminium strip is placed in a steel die; a punch whose diameter is smaller than the monobloc can by an amount twice its wall thickness then forces the slug into the die at high pressure (2,500 kN).The aluminium is plastically deformed with generation of heat (180 to 200 °C), flows past the punch in the opposite direction to the action of punch and takes on the shape dictated by the die. The extrusion process (Fig. 11) only lasts a fraction of a second. The thickness of the bottom is determined by the immersion depth of the punch, which is subsequently withdrawn with the can body from the die; the punch passes through a stripper which separates the can from the punch. As a result of cold working, can bod- ies have high strength, a smooth surface and high dimensional accuracy.

The edge of the can, which becomes slightly wavy as a result of the extrusion process, is trimmed and the sur- face brushed to remove any traces of the impact extrusion. The can body is cleaned inside and out to remove any ab- raded particles and the lubricants used to grease the slugs. Annealing of the can with resultant cleaning (as in the case of tubes) is not possible because the cans have to be hard and maintain their shape. The metal surface is thus de- greased using an alkaline cleaning solution, lightly pickled, rinsed and dried.

The can is then lacquered on the inside to prevent the con- tents coming into direct contact with the aluminium. Epoxy phenolic resin or polyamide imide lacquers are used and applied with a spray can and then baked in using a stove furnace. Further working steps are lacquering of the out- side, printing and lacquer coating with a transparent pro- tective film.

The final manufacturing step is the necking in of the shoul- der in a multiple-die press. This takes place in several steps, the number of which depends on the diameter and chosen shape of the shoulder. Finally, the edge is crimped over and, if necessary, a screw thread is formed; the aperture is milled flat so that it can serve as a sealing surface and a snap-on groove for the lid is formed below the shoulder.

The design of the can opening depends on whether a spray nozzle, a valve or a hand pump is fitted or a thread is need- ed. The necessary preparatory work has to be carried out when forming the aperture. In addition, the bottom of the aerosol cans, which are under pressure, has to be domed inwards. This is also carried out during necking-in if the process step has not been carried out at the pre-production stage. The can is forced into a suitably shaped die.

7.4 Rigid tubes, cases, bottles

Small tubes, cases (Fig. 12) and small tins – for example for tablets, cigars or granule-shaped pharmaceuticals – are also produced by impact extrusion. They usually have aluminium screw-on lids. Aluminium bottles (with a capacity of up to 1 litre) for beer or chemical products are also impact extruded.

7.5 Closures

The screw tops for wide-mouth jars are usually made from aluminium whereas there is competition with other mate- rials when it comes to glass bottles. In the case of the well- known “pilfer-proof” closures on bottles of mineral water, the aluminium top is rolled into the threads of the glass bottle during the closing operation. The ring round the bot- tle neck at the bottom edge of the closure (made of alumini- um or plastic), which acts as a guarantee for the integrity of the contents, becomes separated when the bottle is first opened. For fruit juices, which might ferment, there are even aluminium screw closures available that have been developed with an overpressure safety device.

Semi-rigid packaging includes trays and containers made from thin aluminium strip. They can be produced simply by deep drawing using standard deep drawing presses, are heat resistant and retortable, and are available in the most varied range of colours. They are mainly used for frozen meals and ready meals in catering companies and aircraft catering as well as for portion packs for jam, honey, milk, sausage products and the like (Fig. 13).

There is container strip available to suit all types of con- tents to be packaged: various alloys with thicknesses rang- ing from 0.04 to 0.3 mm are used (the standard range for foil dishes is between 0.07 and 0.1 mm), coated with lac- quer or plastic. Container strip for ready meals comprises, for example, polypropylene, a layer of synthetic resin, thin aluminium strip, baking-in lacquer and printing ink. The containers can be sealed either with plastic film or alu- minium foil. Whereas it was common at one time to use “permanent” seals that had to be cut open along the edge of the container, peelable lids are now widely used.

The good forming properties of aluminium enable the lightweight containers to be produced in the most varied range of shapes. In order to ensure stability, correspond- ingly thicker gauge aluminium strip is used for large-diam- eter containers.

The process steps involved in the deep drawing of contain- ers are briefly as follows: the strip is fed into the tool and a blank corresponding to the size of the finished container is cut out. The tool is lowered into the material and forms the container. The shoulder ring (a part of the tooling that determines the height of the container) is moved into place and the tool is then lowered a little further in order to form the edge of the container. In the process, the rolled edge is folded over some 1 1/2 to 2 1/2 times. The tool then moves upwards again and ejects the container. The whole process takes place in a single stroke; several blanks are shaped simultaneously. Depending on the press type, tool and container shape, a modern deep-drawing press oper- ates at between 70 and 120 strokes/min.

Foil wrappers are one of the oldest applications of alu- minium foil, having been used for chocolate since 1911 right up to the present day as well as having been used for butter, cheese and tobacco products for a long time (Fig. 14). Many of these products are laminated or coated with paper or plastic respectively and are available as sealed or adhesive wrappers, which are impervious or very near- ly so and guarantee the authenticity of the contents.

A further field of application of thin aluminium strip are the lids for dairy products such as yoghurt. The lids are made from material that is 0.03 to 0.04 mm thick with a heat-sealing lacquer on the underside. The lid foils are attached to the plastic container by heat sealing. Capsules made from thin aluminium strip fulfil a decorative purpose on wine and sparkling wine bottles as well as protecting the cork and serving to confirm the integrity of the contents. This applies in a similar manner to the aluminium security foils for beer, which cover the crown cork and guarantee as far as possible the integrity of the contents. In the case of large-area neck foils, the aluminium foil also empha- sises the premium character of the product. The security foils are made from thin foil some 0.010 to 0.020 mm thick.

Impervious membranes made from aluminium foil with or without paper lamination act as proof of originality and diffu- sion protection for instant drinks such as instant coffee or cocoa.

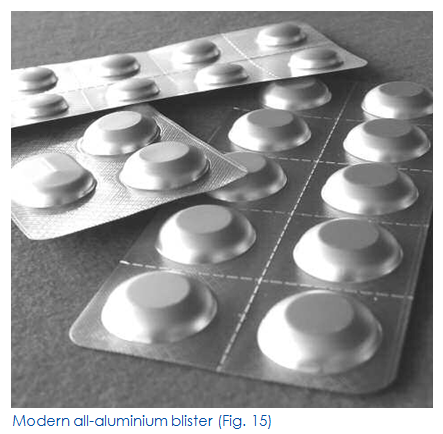

Strip packs made from laminated aluminium foil and push- through packs made from shaped plastic film with a seal- ing aluminium layer are indispensable commercially as blister packs for tablets and pills. The all-aluminium blis- ter, in which both lid and bottom are made from alumini- um foil, has gained in importance recently (Fig. 15).

Retortable pouches, for example for ketchup and ready- meal components containing small pieces of solids, are made from aluminium foil (0.006 to 0.02 mm) laminated with plastic on bag forming, filling and sealing machines. Outside the food sector one can mention pressurised pouches for tennis balls made from an aluminium-plastic laminate; a pressure of about 1 bar is applied to the pouch and this then ensures that there is no loss of pressure inside the balls during storage.

Colour printed and embossed aluminium foil is increas- ingly available as hygienic protection for beverage cans. It is mechanically crimped to the edge of the can, or spot- joined with adhesive, and prevents dust or impurities – caused for example by cans spending prolonged periods on supermarket shelves – entering the can when it is opened. The spot-joined foil is also suitable for temporar- ily resealing the can and thus keeping out insects, for example. With flexo or gravure printing in up to eight colours, the foil can also be used as an effective space for advertising.

Aluminium foil with security features to combat counter- feiting is used for highly sensitive pharmaceutical prod- ucts. These make use of the reflective surface of the metal foil, such as the so-called “pattern shifting” process, which is based on Moiré surface effects. Other processes are based on specially coloured layers, which cause colour shifts when the incident light on the surface of the alu- minium foil is reflected. Yet other processes are based on the partial metallisation of plastic films with aluminium.

Strictly speaking, aseptic packaging for UHT milk is not aluminium packaging but a drinks carton – a laminate of paper, aluminium foil and polyethylene to be precise. The pack material is immersed in a warm bath of hydrogen peroxide to sterilise it. It is subsequently shaped into a so- called Brik-Pack, filled and sealed. Of the around 28 grams of packaging used for a litre carton of UHT milk, the one and a half grams of aluminium foil provides the barrier layer against external influences and helps ensure that the milk can be kept for several months without refriger- ation.

For the sake of completeness, mention should also be made of aluminium household foil (Fig. 16), which does not quite fit into the approach adopted here but still involves the packaging of foodstuffs – whether it be for cooking or storage. It is typically 0.01 to 0.02 mm thick without any printing, wound onto a cardboard reel and available in dif- ferent widths and lengths.

Aluminium tubes are produced by impact extrusion without a seam as a single piece in a similar manner to aerosol cans. The tube material is commercially pure aluminium (99.7% purity) and tube diameters range from 11 to 60 mm. The approximately 0.1 mm thick aluminium tube cylinders are readily deformed plastically with little elastic spring-back. The contents of the tube can thus be dosed into the tube cylinder without any contents or air having to be sucked back out. This makes the tube particularly well suited for everything that has a pasty consistency, ranging from food- stuffs to paints, adhesives and lubricating grease and in- cluding cosmetics (Fig. 17) and pharmaceutical products.

Manufacture: The slug is placed in a steel die and then a steel punch applies a force of up to 1,000 Newton per mm2 on the slug; the aluminium is deformed and adopts the shape dictated by the tooling. Already during this impact extrusion process the pierceable membrane at the tube opening is produced which assures temper-evidence. In addition to cylindrical tubes, there are conical designs in which one opens out the cylindrical tube by one or two degrees in a conifying machine in an additional process- ing step. This allows the empty tubes to be shipped inside each other, which simplifies transport packaging and leads to a significantly reduced shipped volume.

After impact extrusion, the raw tubes are cut to length in automated machining centres, the threads are rolled into the necks of the tubes and the mouths of the tubes are deburred. The tubes are then fed into a continuous fur- nace and annealed so that the cylinders become soft and thus plastically deformable. In addition, the annealing treatment achieves the necessary level of cleanliness for subsequent internal lacquering and printing.

Finally, the aluminium or plastic tube closure is fitted. Screw closures with metric or fine threads as well as twist or flip-top closures are used.

The closure of the tubes after filling is carried out by fold- ing: the tube cylinder is pressed together at the open end with folding tongs and folded over several times to pro- duce a double, triple or saddle fold. Imperviousness is achieved by subsequent pressing. In the case of particu- larly runny substances, a sealing strip of lacquer is applied to the inside of the tube end during production of the tube. One can achieve an even better seal using a heat-seal lac- quer and heat-sealing by pressing the fold with heated pressure clamps.

In addition to the all-aluminium tube, laminated tubes, which are composites of a polyethylene film on the inside and outside with aluminium foil as a barrier layer, and all- plastic tubes are also available.